RAPID BIKE REVOLUTION FOR LAMBDA SENSOR MANAGEMENT

Adopting electronic technology for engine management requires a number of sensors to control the amount of fuel being injected and maintain a balanced carburetion. The amount and quality of intake air coming through the engine and mixed with fuel is affected by different factors such as temperature, pressure and humidity rate: this is the reason why bike performance is likely to change considerably with unpleasant consequences for the rider.

LAMBDA SENSOR: WHY IT WAS CONSIDERED AS A PROBLEM

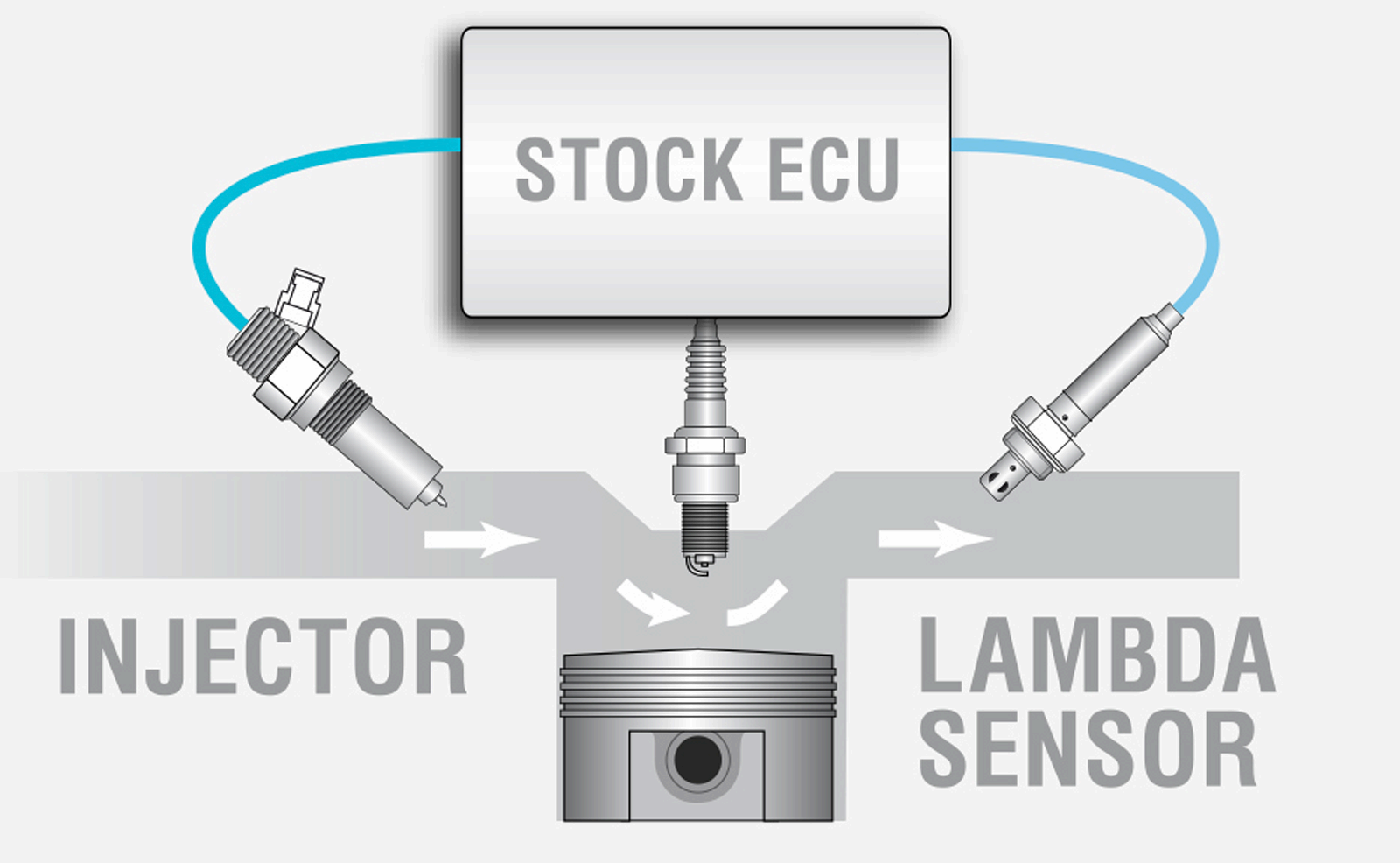

Stock lambda sensor measures the quantity of oxygen in the exhaust gases while OEM ECU (Engine Control Unit) determines the air fuel ratio (air quantity in proportion to one unit of gasoline) to compare it with the value pre-set in its memory and modify the related injection timing.

Bike manufacturers adopted the lambda sensor installed on the exhaust system to monitor the carburetion values in order to comply with increasingly restrictive anti-pollution regulations. This system represents a real constraint for engine performance as it is forced to run with very lean fuel mixture while causing lack of throttle response and sudden power gaps. Here is why lambda sensor is often perceived as a major problem preventing the engine from exploiting its full potential.

RAPID BIKE PROVIDES THE SOLUTION!

Rapid Bike technology is very simple, yet quite innovative since it takes advantage of stock lambda sensor to improve engine efficiency while optimizing fuel consumption.

The goal is not to eliminate stock lambda sensor, rather to perform a dynamic modulation of this signal in such a way to result fully compatible with new injection values set by the add-on module.

This solution helps the whole system (OEM ECU + Rapid Bike) to be more reliable, and to prevent benefits of improved fueling from being perceived as a mistake requiring a further correction. As a matter of fact, Rapid Bike add-on module changes the amount of injected fuel (as it controls directly up to 8 injectors) while modulating stock lambda sensor signal in such a way that OEM ECU will not detect any difference in the air fuel ratio.

Such an innovative solution puts ‘out of the game’ poor and inefficient attempts to eliminate stock lambda sensor signal with devices no longer useful for an efficient management of latest fuel injection technology.

AUTO-ADAPTIVE FEATURE: OUR EXCLUSIVITY

Rapid Bike additional advantage is the ability to stabilize the best fueling values reached with using the add-on module, a system which is similar to the ECU working criteria. The new and innovative autoadaptive feature allows Rapid Bike module to compare the air/fuel ratio target value (set within the module’s map) with the signal reported by the stock lambda sensor. The result of this continuous comparison determines whether the fuel being injected needs to be increased or decreased, and secure the engine always delivers the best performance.

FREE YOUR MIND FROM THE OLD CONCEPT OF A SET INJECTION MAP

This advantage is even more useful when performing some consistent modifications to the bike (such as the installation of a free-flow air filter or a racing exhaust system) requiring the injection map to be modified – Rapid Bike module is able to develop and implement these changes automatically, while the rider is using the bike.

Rapid Bike overcomes the “old” idea of an injection map conceived as a value remaining fixed overtime. Our add-on modules offer the unique feature to develop an injection map and keep it constantly

adjusted making the proper modifications without any need of external operations. Such a technology is so far advanced that a Rapid Bike module will complete the auto-remapping injection process within 200 km ride even in case of starting with a ‘zero’ value map.